Machinery Trends

SW: Reflecting on the past year, have machinery sales increased during the pandemic, decreased or stayed roughly the same?

TE: Labor shortages continue to plague our industry. It’s very hard to find skilled labor, which isn’t a shock to anyone. In addition to labor shortages, the leading indicators for the countertop industry are very optimistic. New home construction and remodeling is booming. The combination of a booming market and labor shortages results in the need to automate processes. Rather than investing in labor (labor that is hard to find), fabricators are investing in automation to meet the market demands. With machinery lead times extended, it is important for fabricators to plan ahead if they want to take advantage of the Section 179 tax and depreciation incentives in 2021.

Park Industries

Todd Eccless, sales manager

SW: In your opinion, what types of features on machinery have been the most beneficial during the pandemic for fabricators?

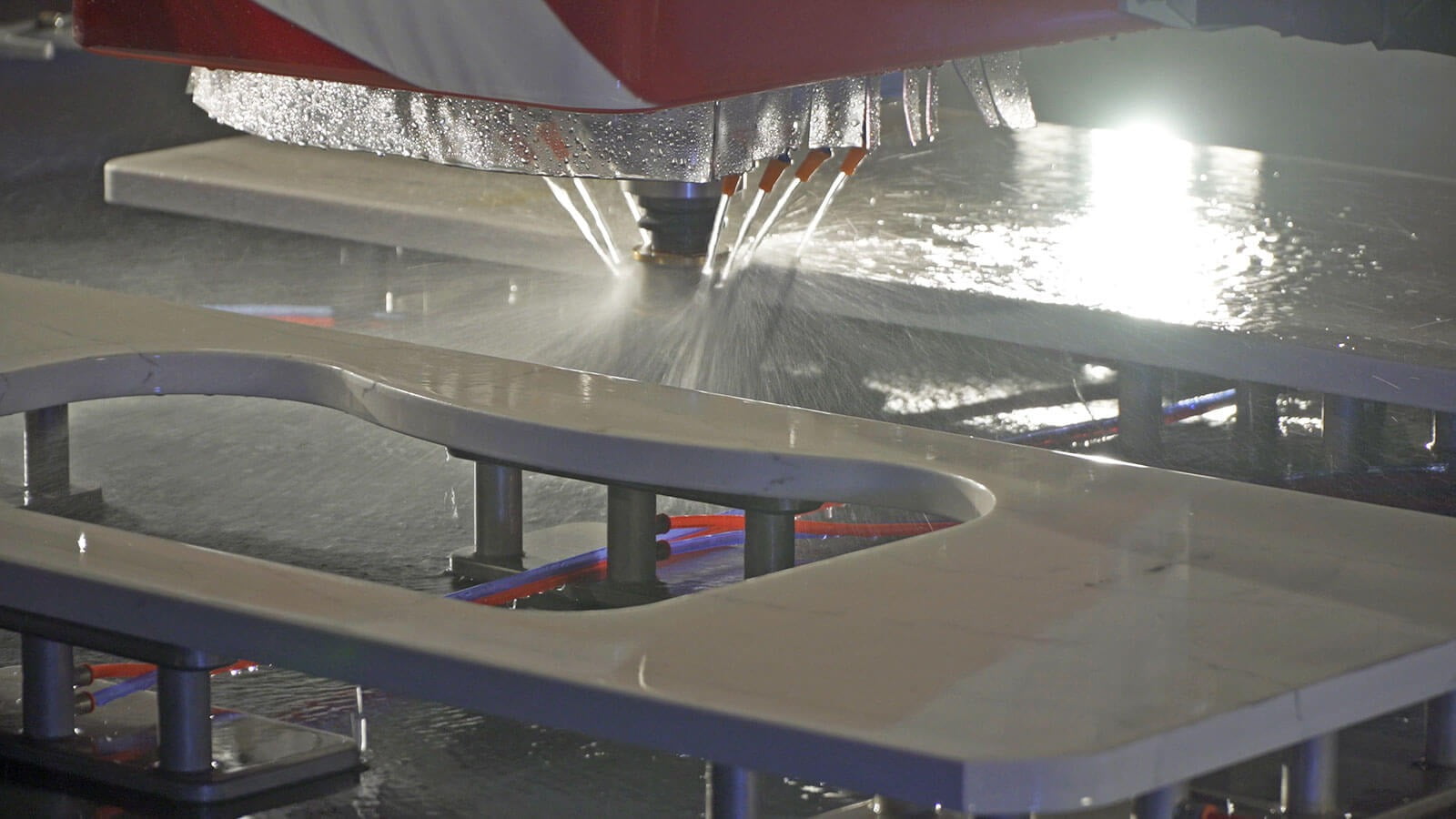

TE: We have seen a shift from manual machinery to more digital machinery, such as our Voyager XP CNC Saw, Saberjet XP CNC SawJet, and our Titan CNC routers. As we look at design trends, flat-eased and miter edges remain very popular. As such, it’s important for fabricators to miter on their sawing station to maximize shop efficiencies. The miterjet feature on our Saberjet XP series and our patented slab loading table have been extremely popular. In addition, we recently launched a SlabBack feature on our Fastback Flat-Edge Polishing system which accommodates slabs up to 96 inches tall.

SW: What are new innovations you are seeing in machinery out there?

TE: The introduction of high-speed tooling has changed the CNC router industry, allowing fabricators to push more productivity through their routers. To take advantage of this productivity improvement, Park Industries introduced a number of kits that can be applied to older Titan CNC routers so that they can run the high-speed tools. Our new Titan 3000 CNC router series was specifically built to manage high-speed tools.

So, you may be asking, what’s next? Park Industries continues to drive research and development …but, you’ll just have to wait in anticipation for the new product announcements.

SW: How do you go about deciding what new machinery advances are needed for fabricators? Is it all at once? Or do you take turns looking at different machines? Do you come up with the ideas by yourselves or is it based on feedback you receive?

TE: Research and development is critical to advance the industry. At Park, we have an entire team of product managers and engineers focused on the future. Many customer interviews and meetings take place as we are developing a new product for the market.

SW: Are you finding lead times for new machinery to be quicker or longer these days, compared to pre-COVID times?

TE: We are experiencing longer leads times, compared to pre-COVID, which is driven by fabricators investing in technology to advance their business. Remember, with longer lead times, it is important that you plan ahead if you want to take advantages of the 2021 Section 179 tax and depreciation benefits. Please reach out to any of us at Park Industries and we would be happy to visit with you regarding your shop’s bottlenecks and how we might be able to help you.

April 2021 | www.stoneworld.com