Experts Share Best Practices for Installing Porcelain Panels in Showers

by Jason Kamery

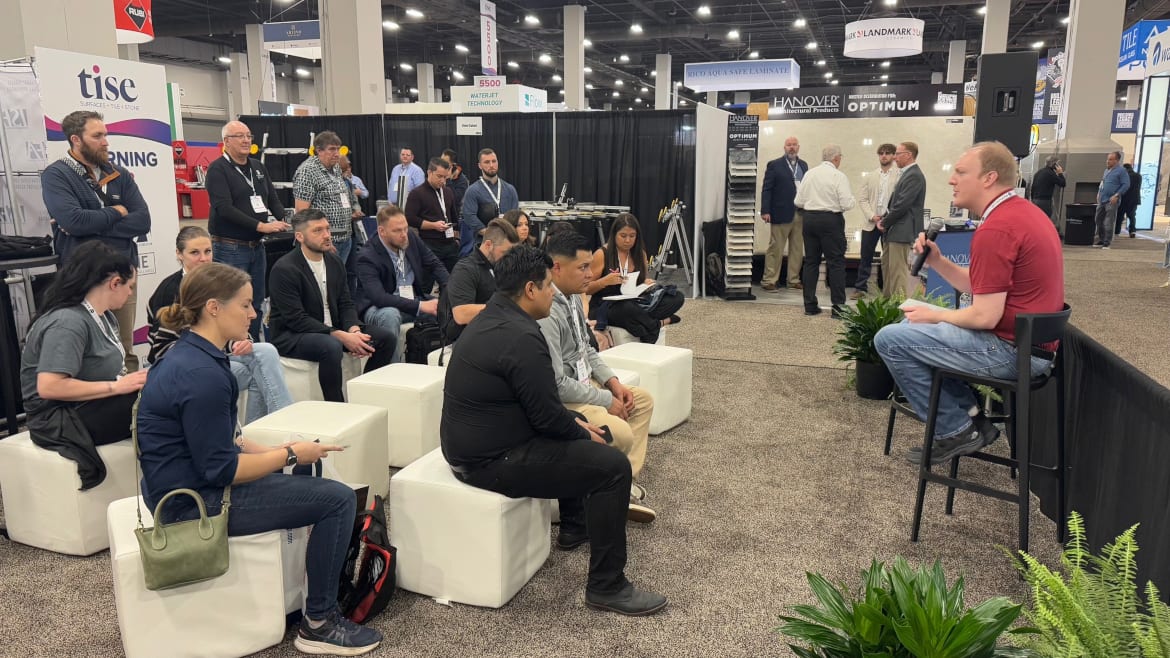

Photo by Jason Kamery of Stone World

The Stone Fabricator’s Alliance (SFA) Cage at TISE drew a crowd of fabricators to learn the intricacies of installing 6-mm porcelain panels over a clean prep shower, with experts emphasizing the importance of a flat substrate, proper adhesive application and advanced troweling techniques.

The session, presented by Lusso Porcelain and Design, highlighted the necessity of preparing a substrate flat within 1/8 inch over 8 feet to ensure a durable installation. It was stressed that regardless of porcelain thickness, a level base is critical for success.

For adhesive, a flexible option like Bostic Bosti Set was recommended for wall and ceiling applications. The double-comb method — applying thin-set mortar to both the substrate and the panel’s back — emerged as a key technique. Experts advised using a gar-notch trowel to meet bond code requirements of 316 square inches per inch, paired with directional troweling from the center outward to expel air and secure adhesion.

Water management proved another focal point. Too much water in the thin-set mix can create bond breakers, causing premature setting and complicating removal. A sponge can be used to lightly wet the mix after waterproofing the shower, but precision is essential.

For larger panels, a support rack or panel handler, was recommended, along with vibration and thumping techniques to activate the thin-set’s properties, ensuring a uniform coat. Expansion joints of at least 1/8inch around the perimeter were deemed vital to accommodate movement and prevent cracking.

The Schluter System, paired with its thin-set, was praised for its lifetime warranty and compliance with industry standards. Meanwhile, the MLT mechanical edge-setting system was touted for holding panels in place during curing, with metal inserts and a 24-hour drying period before removal to maintain structural integrity.

Grout joints sparked debate, with white silicone favored over epoxy for its aesthetic appeal. It was also cautioned against using silicone for adhesion, particularly around fireplaces, where Bostic Bosti Set’s longer open time and strength shine.

Attendees posed questions about integrating 1/2-inch safe boards with porcelain, to which experts advised full troweling and strict adherence to manufacturer guidelines.

Rod Sigman CTC, CCTS, CSMTT is the business development leader for MAPEI Corporation’s UltraCare® line of products for the care and maintenance of tile and stone products. Sigman has a proven track-record of success in the flooring industry, with experience in both training and education, as well as all support functions pertaining to national sales accounts and distribution. He has served on the technical committees of the National Tile Contractors Association (NTCA) and the Natural Stone Institute (NSI). He has successfully completed the Ceramic Tile Consultant Course, is a Certified Ceramic Tile Specialist (CCTS) and is also a Concrete Slab Moisture Testing (CSMT) Technician. Further, he was recognized by the Marble Institute of America (now the Natural Stone Institute) as a significant influence for the stone industry.