Unfortunately, You're Not Bonding to Tile!

Learn the ANSI standards regarding bond strength requirements to ensure a proper tile installation

by Mike Micalizzi

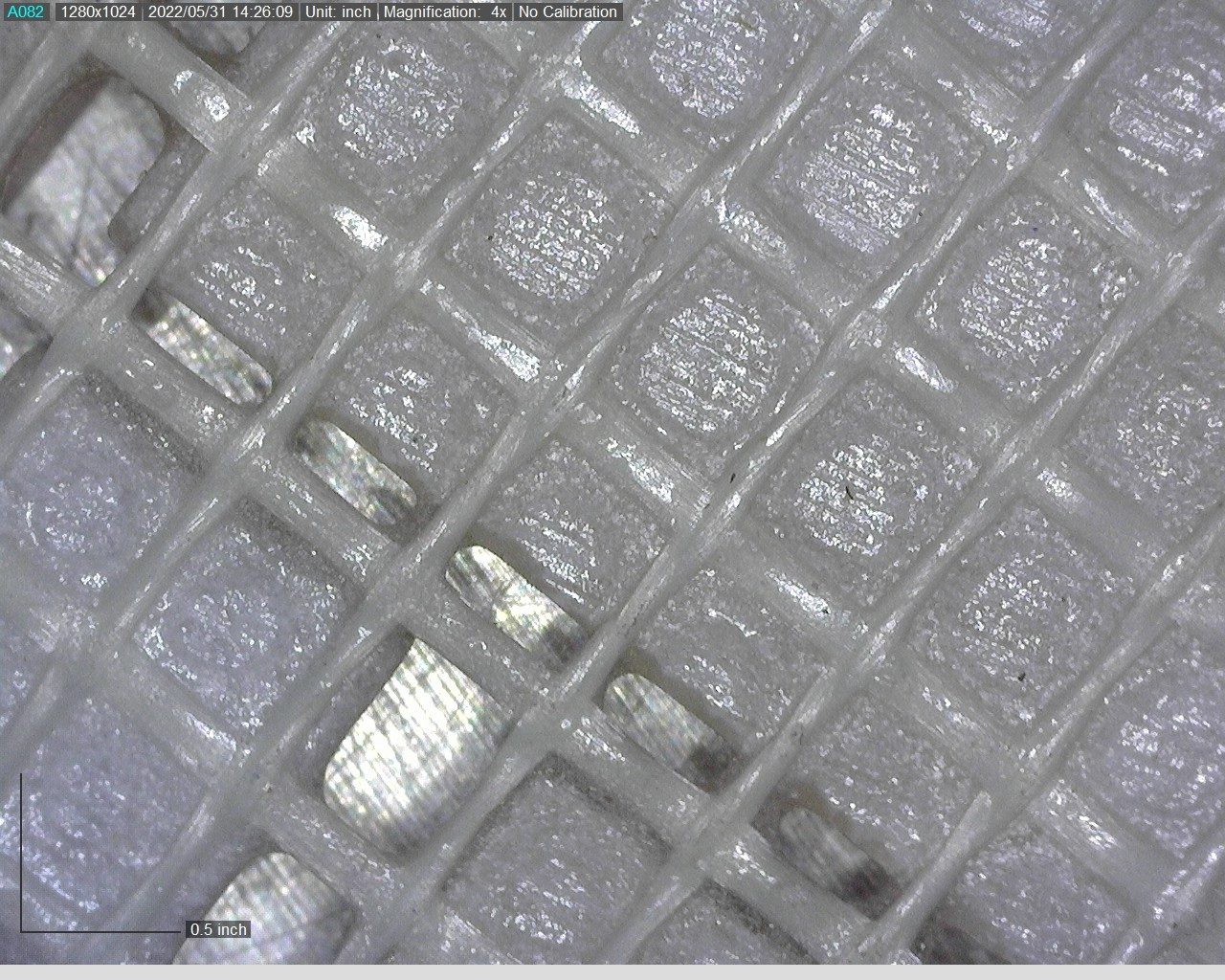

Mosaic tile underside with partial backing

Photos courtesy of Custom Building Products

You may be “setting” tile, but if they are coated or back-layered, you are not “bonding” to tile! Fortunately, the ceramic tile industry has clearly defined both tile manufacturing requirements and installation material performance using ANSI standards, so there is no question regarding bond strength requirements. These minimum values for mortars and adhesives are what specifiers rely upon for bonding porcelain, quarry, bisque and glass tile. Tile installation products have proven success rates, and the standards help protect project owners and contractors. In fact, bonding mortars often exceed building code bond requirements.

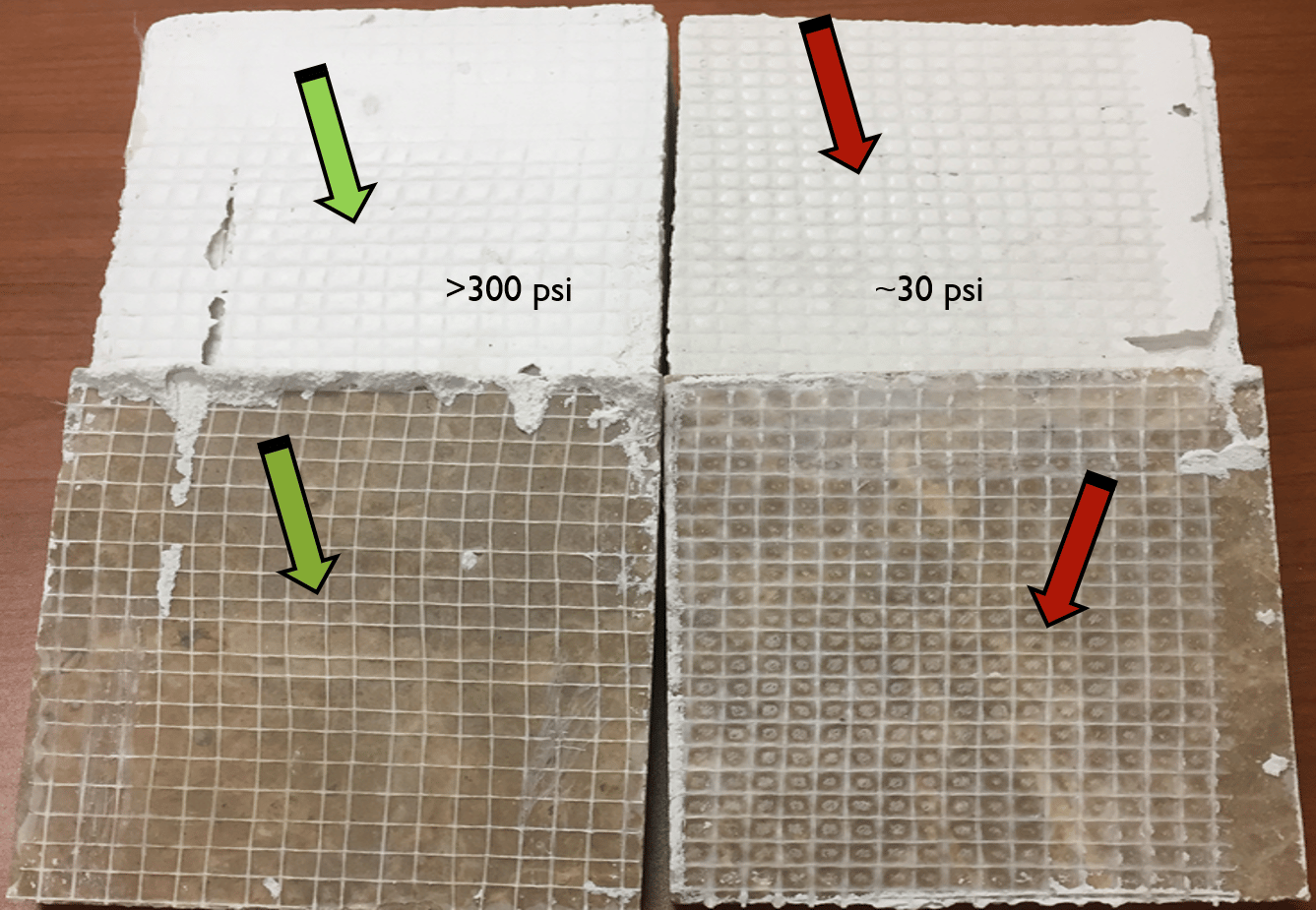

But all too often, tile and natural stone arrive with coatings or backings on their undersides that either hold patterns together or reinforce tiles to prevent breakage during transport. Translucent or transparent glass tiles may have an underside coating to add design elements or to prevent mortar from showing through. Mosaic glass tiles may have a reinforcing backing along with a coating. When this happens (see photos), you are either bonding to only a percentage of the tile surface -- or not bonding to tile at all. Required mortar coverage to the tile underside is ≥80% in dry areas and ≥95% in exterior and wet areas per the ANSI standards. This is impossible to achieve with backings that limit or prevent access to the tile itself.

Consequently, the bonding standards previously relied upon are no longer relevant. Making matters worse, most tile manufacturers have limited information on suitable installation materials for their specialty products and project schedules often limit bonding evaluations.

The exception for backing standards is for manufacturers of Back-Layered Gauged Porcelain Tile Panels. ANSI A137.3 Table 4 specifically requires a minimum of 150 psi (1.03 Mpa) dry and 100 psi (0.69 Mpa) wet shear bond test values using cement-based mortars. As these formats are often used high overhead on interior and exterior walls, having these requirements can truly be lifesaving.

So, why are these tile backings so unpredictable? Mainly, it is because the composition of the backing determines which mortars or adhesives will bond. Backing adhesives are typically Poly Vinyl Acetate (PVA), polyester resin, epoxy or urethane-based, but as tiles are manufactured in many different countries, the backing compositions and their performance will vary greatly and are not standardized. While mortars with high polymer content are usually acceptable to bond to PVA or polyester resin coatings or backings, occasionally they are not compatible and only mockups will provide assurance. ANSI A118.15 Improved (High Performance) Dry-Set Mortars with >600psi shear bond strengths are recommended for back-layered tiles on exterior applications.

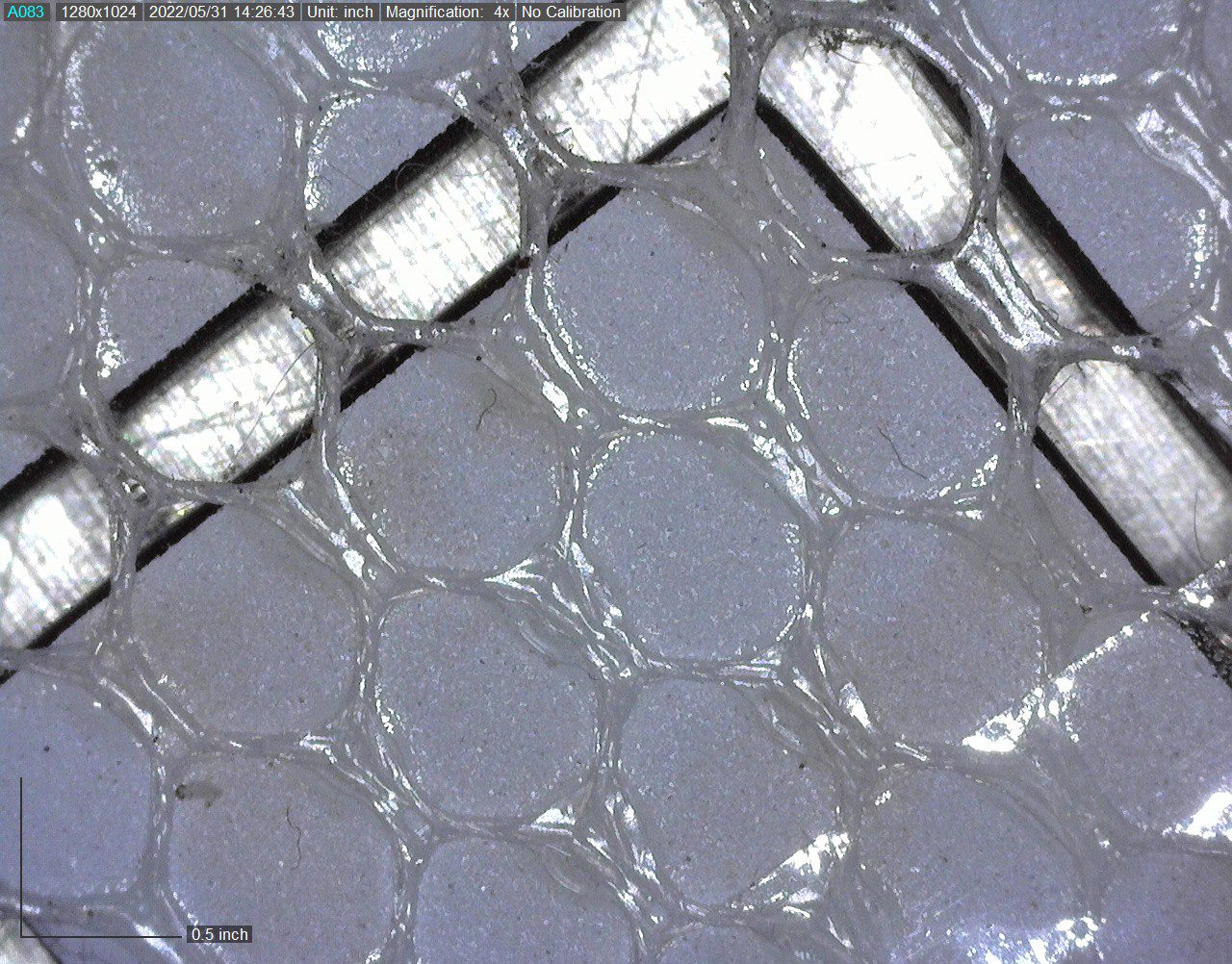

Backings dissolving in water and loosening tile

Epoxy backings require epoxy adhesives or using bonding primers to the tile underside to allow cement mortar bonding. When coarse sand is broadcast into an epoxy backing, a cement-based adhesive mortar may be used to mechanically bond to the sand if it is exposed. If the epoxy encapsulates the sand, it does not allow for adequate strengths using mortars. The installation material manufacturer or an independent laboratory such as the Tile Council of North America (TCNA) can verify bond strengths of specific adhesive mortars.

Generally, PVA compositions are not soluble in water, but with the absence of standards, it is not uncommon to see adhesive backings that actually dissolve when in contact with mortars or water. A simple 48-hour water immersion test has saved many projects from using tiles with dissolving backings in wet areas that could fail. Let the buyer beware, as some of these tiles have been recommended for showers or pool applications. Solubility testing of any backing is a must in wet areas to help prevent costly bonding failures.

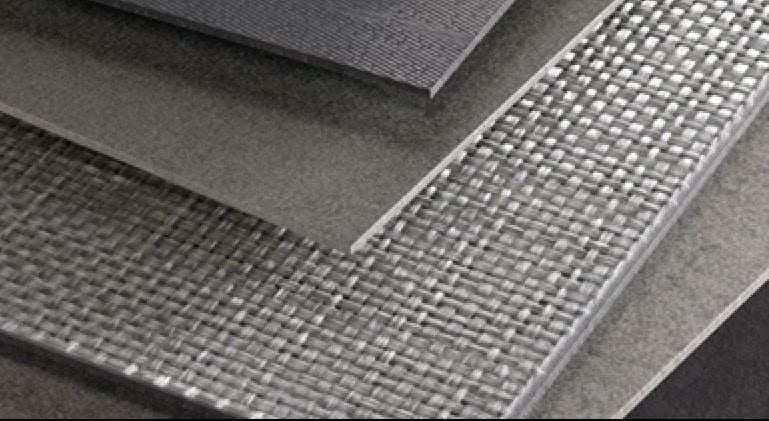

Same natural stone but different reinforcement and adhesive thickness

Some other factors that can cause the failure of backings are their glossiness and thickness. Thicker applications can greatly reduce bond strengths as the films become more deformable. When very glossy, their smooth surface inhibits the mechanical bonding of cement-based mortars. This can be especially problematic in areas with high humidity and/or high heat.

Special care should be taken when using patterned tile sheets with resin backings in wet horizontal applications. When resin-backed tile sheets are installed over a pitched mortar bed, water may not flow through the backing and reinforcing to reach the bed and weep holes around a drain. Water is now trapped in the grout and adhesive and can lead to unsightly staining, grout deterioration or eventually affect adhesive bonds.

When adhered with cement-based mortars, tiles are subjected to high alkalinity. Specialty tiles (those not conforming to ANSI A137.1, A137.2 or A137.3), are often mounted using resin and mesh backings. These tiles may be composed of various metals, mirrors, quartz, wood or plastics and can be stained or break down with long-term exposure with cement. Some may have reactions to grouts as well, increasing the additional need for evaluations, mockups or ANSI bond strength testing.

Glossy adhesive backing

Due to the complexities associated with tile backings and until standards are developed, involve your installation material representatives early in the project to review the specification, assist with product selection, warranty requirements, mockup evaluations and technical support at the project startup. Plan to conduct mockups to look for the potential effects previously discussed and gather as much information as possible when backings are included. Also, for best results for the installation, specify the use of a qualified installation company as described below:

Installer Qualifications:

- Company specializing in performing the work of this section with minimum five years documented experience.

- Installer shall be a five-star member of the National Tile Contractors Association (NTCA) or a Trowel of Excellence member of the Tile Contractors' Association of America (TCAA).

- Installer's on-site supervisor shall hold the International Masonry Institute's Foreman Certification.

- Installer shall employ Ceramic Tile Education Foundation Certified Installers or installers recognized by the U.S. Department of Labor as Journeyman Tile Layers.

- Installer employs at least one installer for Project that has completed the Advanced Certification for Tile Installers (ACT) certification for installation of [mud floors] [mud walls] [membranes] [shower receptors] [gauged porcelain tile/gauged porcelain tile panels and slabs] [and] [large format tile].

Mike Micalizzi is the senior director of technical services for Custom Building Products. He is based at their research and training facility, Custom Technical University, located in Santa Fe Springs, CA. In this role, Micalizzi assists industry professionals with recommendations on commercial projects presenting a variety of installation challenges. He also presents the “Top 5 Tips” educational video series for tile contractors and design professionals.

Prior to becoming involved in product technology, Micalizzi owned a tile and stone installation company in New Haven, CT. He currently serves on technical committees for the Tile Council of North America (TCNA), Materials & Methods Standards Association (MMSA), National Tile Contractors Association (NTCA), Natural Stone Institute (NSI), American National Standards Institute (ANSI) and ASTM International.

About the Author