What to Know About Profile Selection for a Successful Tile Installation

With a broad spectrum of profiles available to meet the demand of different materials and environments, an installation will last for years to come as long as the appropriate one is chosen for that particular application

by Kali Pharand, technical services department, Schluter Systems

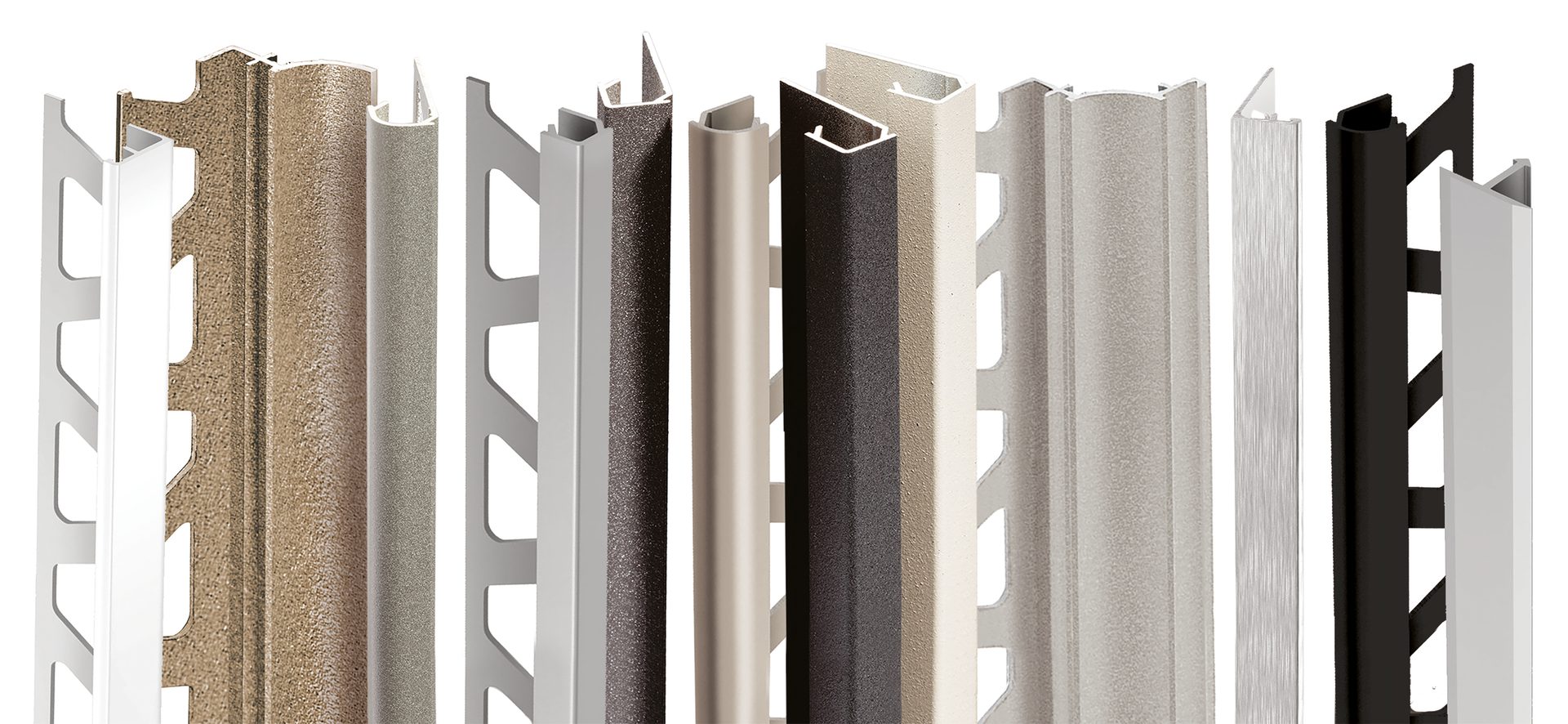

With a range of styles, colors and designs, Schluter profiles help protect tile assemblies over a wide variety of areas of use.

Photo courtesy of Schluter Systems

Profiles are strips of metal or plastic designed to cover and protect the edges of a tile or other surface covering in floor and wall applications. Often, they are used as an alternative to bullnose, cove base, and other traditional ceramic trim shapes. With an increasing number of tile installations coexisting with other surface coverings, the need arises for appropriate transitions within and around the tiled surface. Profile pieces provide aesthetically pleasing transitions between a wide array of surface coverings of varying thickness, such as tile, stone, carpet, laminate, gauged porcelain tiles and tile panels, a wood flooring and luxury vinyl tiles (LVT). Regardless of the chosen surface covering on both floors and walls, profiles add value to any tile project without compromising the budget.

Movement Joints

In addition to allowing for transitions to other surfaces, some profiles include movement joints either at the perimeters or within the tile installation. These profile pieces include strips composed of flexible chlorinated polyethylene (CPE) within the center of the profile that expand and contract based on the temperature, moisture and other factors that can contribute to movement within a tile installation. Movement accommodation is necessary in all floor tile applications, as it prevents tile from cracking and tenting (tile bending and moving upwards) due to movement. The requirement for movement joints for the tile industry is covered in the EJ-171 detail in the Tile Council of North America’s (TCNA) Handbook. However, some installers fail to incorporate movement joints into tile or natural stone installations due to lack of knowledge and/or misunderstanding. In areas subject to freeze/thaw, structures are more prone to expansion and contraction due to the drastic change in temperature, and movement joints will accommodate this movement to protect the tile or stone field. Failure to incorporate the necessary movement joints will result in damage to the surface covering over time. Movement joint profiles are recommended to be installed at a maximum of every 20 feet in any direction based on the size of the tiled surface, and EJ 171 explains when more frequent movement joints may be required, such as in areas with full sunlight. For more information on movement joints, such as how to install them and where to apply them, refer to the Schluter Systems®-DITRA Installation Handbook (enter QR code for handbook) and the TCNA Handbook.

Failing to provide the adequate movement joints in an application can lead to cracking tiles.

Photo courtesy of Schluter Systems

Schluter®-DILEX-EDP is a heavy-duty stainless steel surface joint profile that separates individual field in the tile covering, ideal of areas exposed to heavy traffic.

Photo courtesy of Schluter Systems

Interior Dry Environments

With the rising need for the appropriate surface covering transitions, profiles are becoming widely available in many different sizes, shapes and finishes to benefit the needs of the designer and installer. There are many profile finishes that are recommended for use in temperature-controlled, interior environments. Such finishes include aluminum, anodized aluminum, color-coated and textured color-coated aluminum, solid and chrome-plated solid brass, polyvinyl chloride or soft polyvinyl chloride (PVC/soft PVC), stainless steel (304 and 316 L), thermoplastic rubber, CPE and mineral grain. Because of the vast array of finish options, it is likely that tile installers, homeowners and/or builders will find profiles that are aesthetically pleasing and fit well into any application.

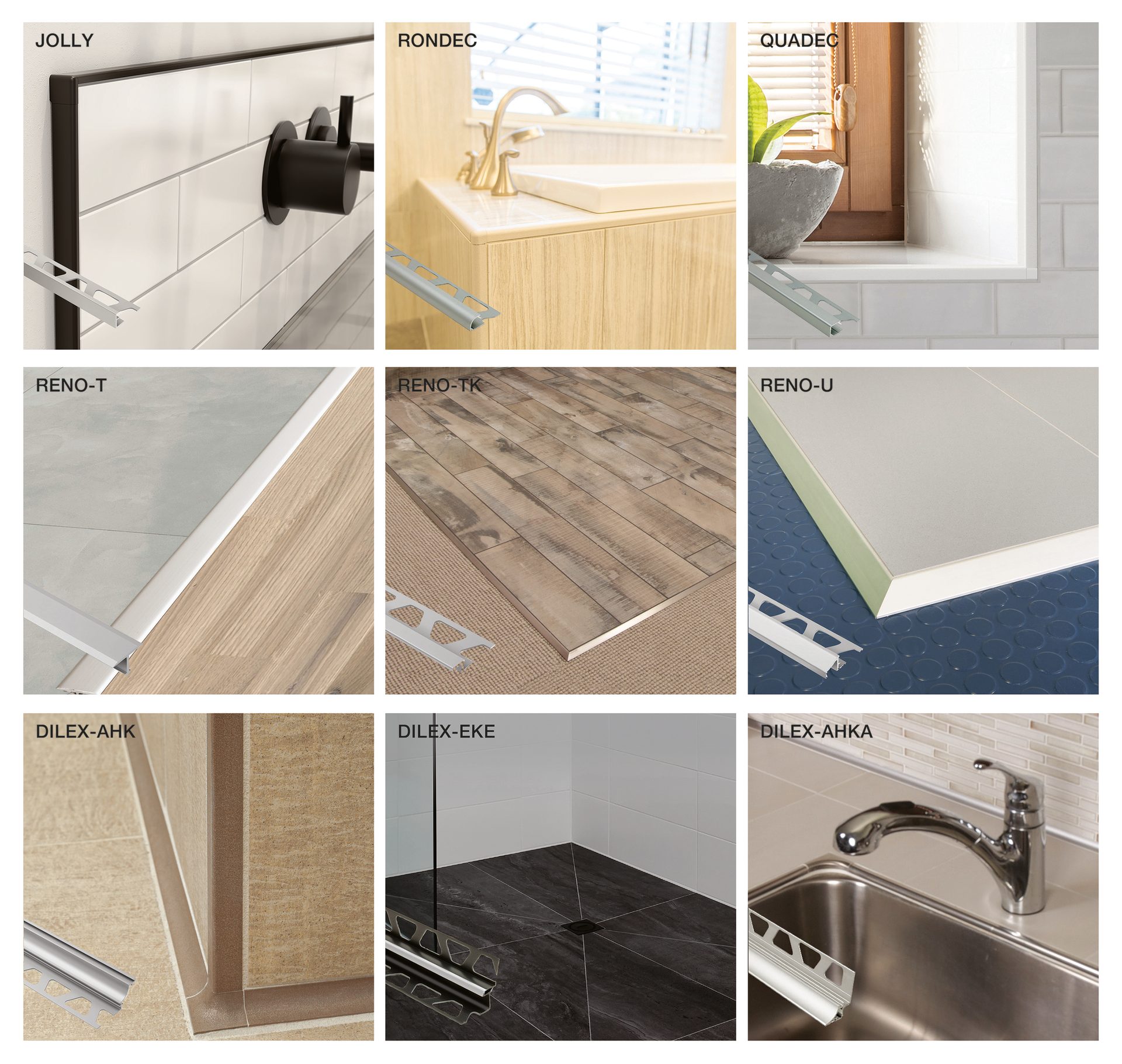

Whatever the application, there is a right solution for every tile project.

Photo courtesy of Schluter Systems

Interior Wet Environments

Due to the moisture affecting the finish of some profile finishes or coatings, stainless steel 316 L is the recommended choice for interior areas subject to moisture, such as bathrooms, steam rooms and saunas. As long as the profiles applied in wet environments are well maintained, the stainless steel will fare well, and its finish will be long lasting. Stainless steel is also the recommended finish for commercial areas subject to chemicals and acids, such as in the food industry in commercial kitchens within restaurants and hospitals. Although many finishes are approved for use in interior environments, routine maintenance must be observed.

Schluter Systems provides many solutions to create a desirable steam shower.

Photo courtesy of Schluter Systems

Exterior Environments

The list of profiles approved for use in exterior environments is limited based on the rigors of exterior exposure. The location of the installation must be taken into consideration when choosing the specific finish, as harsh conditions in areas subject to freeze/thaw will affect the finish of the selected profile. Nevertheless, the following profiles are suitable for exterior environments: color-coated and textured color-coated aluminum, thermoplastic rubber, chlorinated polyethylene and mineral grain (with the strict exception of the transparent thread, which is only suited for interior use). Swimming pools are popular exterior areas where installers would benefit from the use of profiles. Stainless steel stair nosing profiles, for example, provide striking views from the pool’s surface, not to mention safety while walking into the pool to gradually reach the bottom. Although some of the profiles used in swimming pool applications will be continuously submerged, regular maintenance must be observed to maintain the quality and appearance of the profiles.

Care and Cleaning

In order to maintain the appearance of the profiles, regular maintenance is necessary. Cleaning products used to clean profiles, regardless of the finish and area(s) installed, must be pH neutral to avoid damaging the finish and/or coating. The pH (power of Hydrogen) is measured on a scale of 1 to 14, where 7 is neutral. A pH of less than 7 is acidic (i.e., distilled white vinegar), and a pH of higher than 7 is alkaline (i.e., household ammonia). In addition to being a neutral pH (near 7), cleaners and cleaning materials used for profiles should be non abrasive to prevent scratching. For specific name brand cleaners, refer to the cleaner manufacturer’s safety data sheet (SDS) for the specific pH of the cleaner for a better understanding of which cleaning products to use, and which ones to avoid, to clean the profiles to ensure a profile installation that lasts.

Summary

Tile designers and installers now have a large array of profiles to choose from to end a tile installation and provide movement accommodation without the need for additional caulks and sealant. By choosing the correct material for their installation environment, the designer and installer can ensure many years of trouble-free service. Manufacturers, like Schluter Systems, frequently offer other elements such as drain covers and shelves that match the profiles to tie the entire installation together beautifully.

Kali Pharand works in the Technical Services Department for Schluter Systems at the North American headquarters in Plattsburgh, NY. She has a degree in English Language Arts and brings her passion for language and expertise in technical topics together to ensure Schluter’s handbooks, guides, data sheets and technical articles help to educate, protect and support Schluter’s customers. Pharand’s technical focus includes sustainability, standards and certifications, and how each relates to the company’s products. In her personal life, Pharand is a wife to her husband, Danny, and mother to her two daughters, Avree and Henley. Together they enjoy hockey and other sporting events, live music, movie nights, dancing and camping. For more information on this topic, you can contact us using the contact page at www.schluter.com.

About the Author

Brett Mauney CTC, CTI, is Merkrete’s technical sales manager, managing the company’s extensive technical training. Mauney’s career stretches back to 1988, working all sides of the tile industry to include ceramic tile and setting materials manufacturing, installation, sales and distribution. Since 2007, he has provided comprehensive technical support for Merkrete’s renowned tile setting materials.

About the Author